What is Design for Disassembly (DfD) and Why is it Crucial for Your Recycling Equipment?

- Benjamin Cabrera

- Aug 1, 2025

- 4 min read

Imagine this: You’re running a bustling recycling facility, the conveyors humming, materials sorting efficiently. Then, a critical piece of equipment malfunctions. Your team dives in, only to find themselves contorting into impossible positions, wrestling with rusted bolts in hard-to-access areas, and spending hours—or even days—on what should be a straightforward repair. Sound familiar?

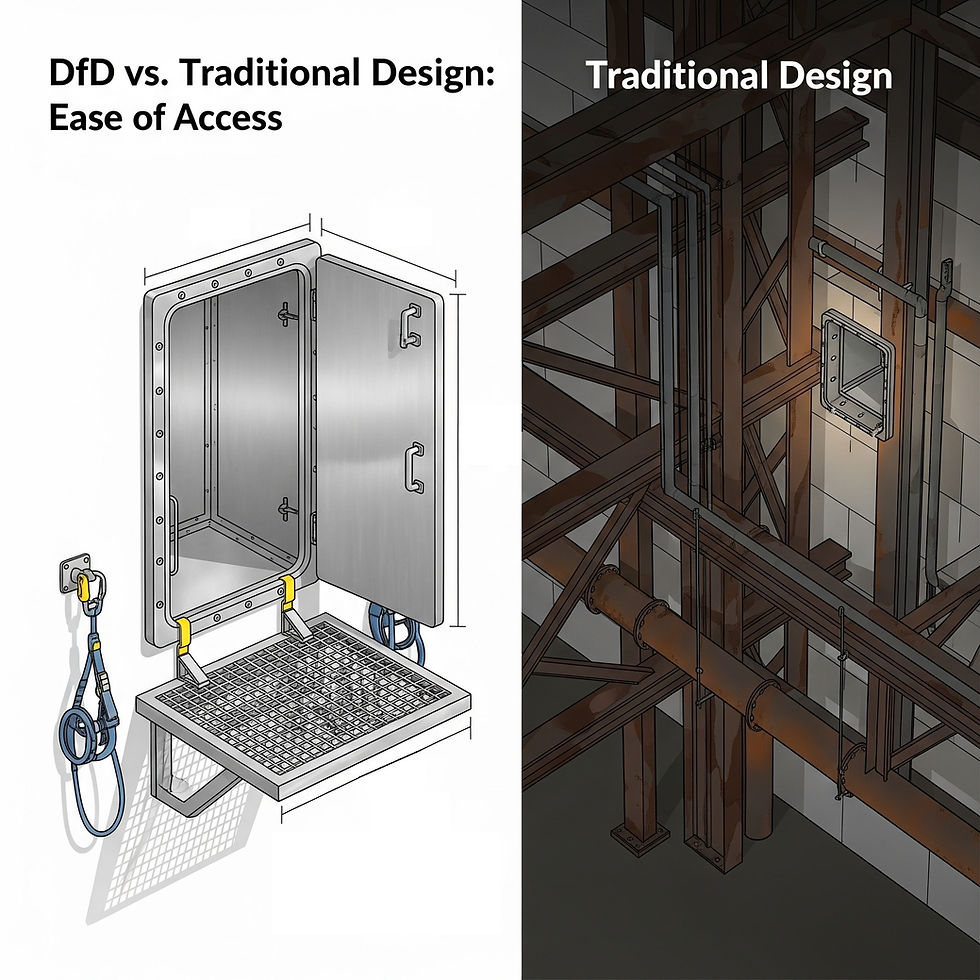

This common scenario highlights a fundamental challenge in the recycling industry: equipment and facility designs that prioritize initial build-out over long-term operational realities. It’s a design philosophy that, while seemingly saving costs upfront, can quickly put you against an operational wall, creating unforeseen expenses and severely limiting your ability to adapt to ever-changing market demands.

The Hidden Costs of Inflexible Design

In an industry defined by transitions and rapid evolution, the ability to pivot is paramount. Recycling markets are dynamic; what's highly recyclable today might be less so tomorrow, or new material streams might emerge. This constant flux means that your facility's design lifetime is, in practice, getting shorter. Retrofits are no longer a rare event but a common necessity.

The core problem arises when your equipment and facility layout are designed without Design for Disassembly (DfD) in mind. This oversight leads to:

Maintenance Nightmares: Difficult-to-access components turn routine repairs into major undertakings. Simple tasks like replacing a worn bearing or clearing a chute of material spills become time-consuming, labor-intensive, and costly.

Stifled Adaptation: When you need to retrofit, redesign, reconfigure, or even consider the relocation of equipment to accommodate new material streams or processing techniques, inflexible designs make these changes incredibly difficult and expensive. What could be a strategic facility update becomes a monumental project.

Unplanned Downtime: Every hour spent struggling with a poorly designed machine is an hour your facility isn't processing materials, directly impacting your bottom line and leading to significant lost revenue.

While bringing a facility's design to life is reliant on its capital costs, a facility will ultimately live and die by its operating costs; much of the operating costs are maintenance and daily flow. This is where DfD shines.

Design for Disassembly (DfD): Your Operational Game-Changer

So, what exactly is Design for Disassembly? At its heart, DfD is a design philosophy that prioritizes the ease and efficiency with which a product or system can be taken apart. For recycling equipment, this means:

Modular Construction: Equipment built in easily separable modules allows for quick replacement, upgrading, or reconfiguration.

Standardized Fasteners and Connections: Minimizing the variety of tools needed and using readily accessible fasteners reduces maintenance time.

Clear Access Points: Designing equipment with ample room for technicians to reach all components for inspection, repairs, and cleaning.

Durability and Repairability: Using robust materials that can withstand repeated assembly and disassembly, and designing components to be easily repaired rather than fully replaced.

The beauty of adaptable designs is that they don't have to be prohibitively expensive upfront. In fact, integrating DfD principles early in the design phase can significantly reduce lifetime facility operations costs.

The ROI of Smart Design

Prioritizing Design for Disassembly (DfD) early on can drastically improve a recycling facility's ROI. By embracing DfD, you’re not just investing in equipment; you're investing in the future adaptability and profitability of your entire operation.

Think about it:

Reduced Downtime: Faster repairs and maintenance mean more uptime and higher throughput.

Lower Labor Costs: Technicians spend less time struggling and more time getting the job done efficiently.

Easier Upgrades and Retrofits: Adapting to new market transitions becomes a streamlined process, not a costly hurdle. Your ability to reconfigure your lines quickly keeps you competitive.

Extended Equipment Lifespan: Easier maintenance and the ability to replace individual components mean your valuable assets last longer.

Improved Safety: Better access reduces the risk of accidents during repairs and cleaning, especially when dealing with material spills.

In a world where flexibility and efficiency are king, DfD is no longer a luxury but a necessity for any forward-thinking recycling facility operator. It’s about building a resilient operation ready for whatever the market throws its way.

Ready to Optimize Your Facility?

Don't let outdated design principles hold your facility operations back. Embracing Design for Disassembly can be the single most impactful facility update you make.

Contact us for a free design consultation! Let's discuss how DfD can revolutionize your recycling facility’s efficiency and profitability during your next upgrade or retrofit project.

Comments