Elevating Recycling Equipment Design: Unlocking Efficiency with Autodesk Inventor

- Benjamin Cabrera

- Jul 10, 2025

- 3 min read

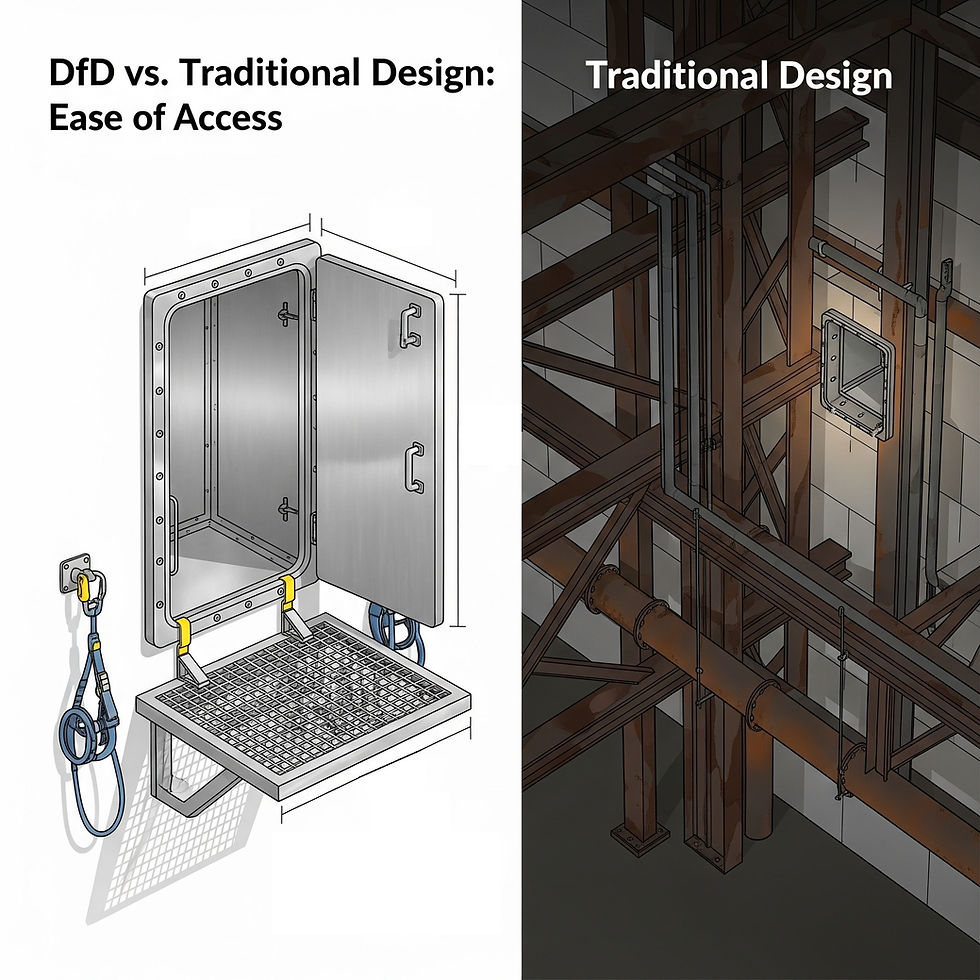

In the dynamic world of industrial recycling, precision and adaptability in equipment design are not just advantages—they're necessities. As projects evolve and material streams diversify, the ability to rapidly iterate and ensure seamless integration becomes paramount. This is where the strategic application of Autodesk Inventor, a leading parametric CAD software, truly shines. From years of experience in the recycling industry, it's clear that effective design goes beyond just creating a drawing; it's about engineering solutions that reduce future workload, minimize errors, and clearly communicate every aspect of a project.

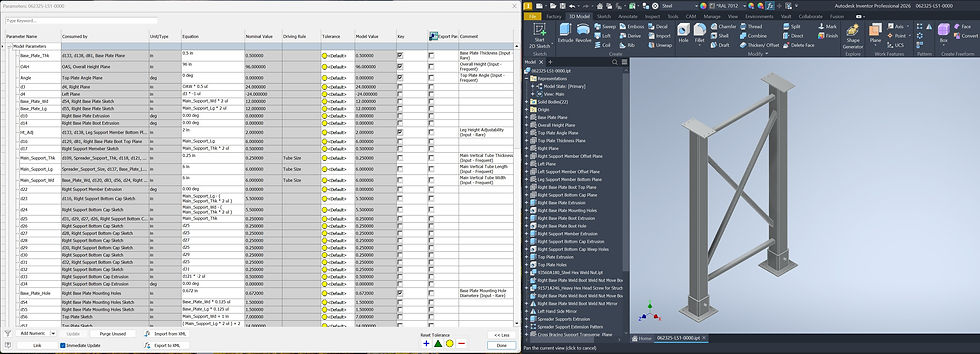

The Power of Parametric Design: Build Smarter, Not Harder

Parametric modeling in Autodesk Inventor fundamentally changes how design works. Instead of static drawings, your equipment models are driven by intelligent parameters—dimensions, constraints, and relationships—that allow for incredible flexibility. This means that if a key dimension changes, or a component needs to adapt to a new layout, the entire model updates automatically, saving countless hours of manual rework.

For recycling equipment, where modifications and retrofits are common, this capability is a game-changer. It ensures that designs are resilient to change and that every adjustment cascades logically through the system, reflecting a design philosophy focused on creating solutions that are "faster, and better than the last one that is similar".

Want to dive deeper into parametric modeling? Explore this beginner's guide to understanding its fundamentals in Inventor: A Beginner's Guide to Parametric Modelling in Autodesk Inventor.

Mastering Design Intent: Clarity in Every Line

Beyond just knowing the software, the true art of CAD lies in mastering design intent. This means planning ahead for unforeseen outcomes and asking the right questions upfront. When approaching a project, it's crucial to not just draw, but to strategically build intelligence into the model itself. This ensures that the final drawings "speak" to all groups involved, from engineering to manufacturing and installation.

By focusing on clear relationships and minimal, purposeful constraints, you can ensure that your designs are not only editable but also "obvious" and easily understood. This reduces misunderstandings, accelerates project timelines, and ultimately saves you time and money. Learn more about delivering clear design intent with Autodesk's official resources:

Practical Tips for Optimized Industrial Designs in Inventor:

Drawing from years of experience with industrial equipment layouts, here are a few best practices to ensure your Inventor models are robust and efficient:

Simplify Sketches: Keep your 2D sketches clean and fully constrained.

Complex sketches can lead to unpredictable behavior when changes are made. Focus on simple geometry and apply dimensions and constraints effectively.

Leverage Built-in Features: For common elements like holes, don't just extrude a circle. Use Inventor's dedicated "Hole" command. This not only makes your model more intelligent by allowing for standard fits (e.g., clearance holes for bolts) but also simplifies drawing annotation.

Organize Your Model Browser: As assemblies grow, a well-organized Model Browser is crucial. Use folders for components and give features and parameters meaningful names. This makes it easier to navigate, understand, and modify complex industrial equipment designs.

Test as You Go: Don't wait until the end to test your parametric model's robustness. As you add features, try modifying key parameters to catch potential issues early. This proactive approach saves significant time in the long run.

By integrating these advanced techniques into your workflow, you can maximize the potential of Autodesk Inventor. This leads to industrial recycling equipment designs that are more efficient, easier to maintain, and seamlessly integrate with existing infrastructure. Mastering these aspects of CAD can significantly benefit your operations, enabling more efficient, durable, and adaptable recycling solutions.

Comments